|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Chisel & Plane Blade Sharpening Service

Chisels & Planes Sharpened

At the Sharpening Shack, we professionally hand and machine sharpen most wood chisels and hand planes. Our hand plane service includes the sharpening of the plane blade and a free plane sole base check, if minor sole flattening is needed, it is included!!! If more than minor flattening is needed, then we will let you know and you can decide if you want us to perform the work.

We can also slightly round the corners of your plane blade at no additional cost if you so request.

Our basic hand plane and chisel sharpening included's the following services:

- Inspection of the base of the hand plane - minor flattening of base of plane included

- Removal of minor rust and dirt

- Removal of minor nicks

- Minor squaring of edge

- Flat Edge Bevel sharpening

- Flattening the back of a blade or chisel

- Honing and mirror/bright polishing of edge

Hand plane & chisel sharpening pricing is as follows:

| Hand Plane Irons (1" and under) | $5.00 |

| Hand Plane Irons (1 1/8" to 2") | $7.00 |

| Hand Plane Irons (2 1/8" to 3 ") | $9.00 |

| Chisels (1" and under) | $4.00 |

| Chisels (1 1/8" to 2") | $5.50 |

| Chisels (2 1/8" to 3 ") | $7.50 |

| Skew Chisel | $7.00 |

Additional hand plane & chisel sharpening services:

____

____

| Hollow Ground Edge Sharpening - (Tormek) ( Done on Tormek Wet Grinder (add $2 to each item) |

$2.00 |

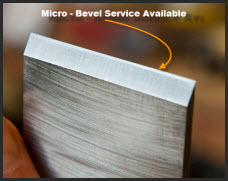

| Add Micro-Bevel Edge ( Done using 4000grit and 8000grit Whetstones (add $2 to each item) |

$2.00 |

| Removal of Large Blade Edge Nicks & Chips or (add $2 for each item) | $2.00 |

| Rust Removal Bath with minor sanding and polishing (add $2 for each item) | $2.00 |

Why Add A Micro-Bevel?

Sometimes referred to as a secondary bevel. This is a narrow bevel (no more than 1/32") applied right at the edge of the blade and is ideally about 2° to 5° greater than the primary bevel. A micro-bevel slightly strengthens the edge and limits the really fine honing required to create a razor-sharp edge to just the tip of the blade, saving wear on the fine abrasive. A micro-bevel also makes any touch-up honing that much easier, since only a small amount of metal needs to be removed from the tip, rather than from the entire bevel.

Why Add A Hollow-Grind?

On a hollow grind, the actual tool angle (at the point) is 2 to 5 degrees less than the apparent tool angle (at the heel), depending on the radius of the abrasive wheel and the length of the hollow face. This reduces the force needed to drive the too land allows for easier touch-ups to sharpen since there is less metal. However, there is a trade-off — a hollow-ground tool has less metal to buttress the cutting edge and it wears faster. For this reason, hollow-grind only light-duty tools such as carving knives and paring chisels. Others are best flat-ground.

Types of Chisels Sharpened |

|

|

BEVEL edged chisels are slightly undercut making them easy to push into corners. They are normally used for finishing dovetail joints.

|

FIRMER chisels have a blade with a rectangular cross-section. This means that they are stronger and can be used for tougher/heavier work.

|

|

PARING chisels is a longer, thinner chisel which can be pushed into long joints such as housing joints. It is used for cleaning up the joint and to make it an accurate fit. |

|

Types of Chisel & Plane Blades: |

|

|

|

Chisels |

Block Planes |

|

|

|

Bench Planes |

Jointer Planes |

San Diego Sharpening Services | Cutlery Sharpened | Knife Sharpening | Garden Tool Sharpening | Hand Tool Sharpening

Mail-Order Sharpening | Ski Sharpening | Lawn Mower Blades Sharpened | Electric Knife Sharpening | Knife Reconditioning

Chula Vista Knife Supply | Contact Sharpening Shack | Pick-Up & Delivery Sharpening Service | Paper Cutter Sharpening | Sitemap

Chain Saw Sharpening | Hedge Trimmer Sharpening | Golf Club Sharpening | Axe Sharpening | Plane & Chisel Sharpening

Hair Scissor & Shear Sharpening | Straight Razor Repair Service